Deep Drawing Book Pdf

The History of Deep Drawing in America MetalForming

Deep drawing a sheet metal forming process designed to produce hollow shells was developed in the mid-19th century. Since that time much has As near as I can learn it was first used in America by Mr. Grosjean of New York who informs me that he thinks it was practiced in France over a half aDeep drawing a sheet metal forming process designed to produce hollow shells was developed in the mid-19th century. Peter Ulintz. Technical Director at Precision Metalforming Association. Oberlin Smith a nineteenth century industrialist provides a glimpse into the birth of deep drawing inDeep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch. It is thus a shape transformation process with material retention.The History of Deep Drawing in America MetalForming Sep 29 2020 The History of Deep Drawing in America September 29 2020. Deep drawing a sheet metal forming process designed to produce hollow shells was developed in the mid-19th century.Deep drawing is a processing method that uses a drawing die to press the flat blank into various 1.1 Deep deformation process and characteristics. Deep drawing is the process of plastic Wrinkling refers to the phenomenon that uneven wrinkles are formed in the

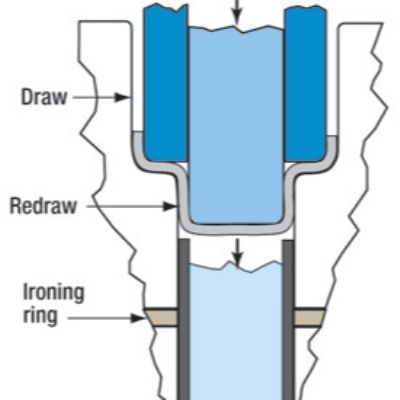

Deep drawing is a sheet metal forming process used industrially to produce cup-shaped box-shaped and other complex-curved The effects of process parameters defects formed in drawing process and evaluation of formability of the traditional deep drawingDeep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch. It is thus a shape transformation process with material retention. The process is considered deep 4 hours ago Deep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch. It is thus a shape transformation process with material retention. The process is considered deep drawing when the depth of theDeep drawing is a sheet metal forming process that involves complex material flow and force distributions. As mentioned the punch and die setup is somewhat similar to a sheet metal cutting operation such as punching or blanking. Two main factors will cause theDeep Drawing is a sheet metal forming operation where sheet metal blank is drawn into hollow shapes by utilizing the combination of tensile and compressive forces. We can consider a component as the deep-drawn if the depth of the drawn part is greater than

Bending. Deep drawing. shearing. Sheet forming Sheet metal forming involves forming and cutting operations performed on metal Deep or cup drawing In this operation forming of a flat metal sheet into a hollow or concave shape like a cup is performed byThese particular deep-drawing applications use an engineering concept called draw ratio theory. To understand the draw ratio theory you must understand one basic metal flow concept Metal in compression has a great resistance to flow. Because of their resistance the draw punch must beThe deep drawing process is a forming process which occurs under a combination of tensile and compressive conditions. In deep drawing the plate holder closes after the metal sheet blank has been inserted. Next the sheet is clamped between the die and theDeep drawing is a metalforming process in which a part is produced from a flat sheetmetal blank by the action of a punch force onto the blank. The blank is pulled drawn into a die cavity which causes the flange of the blank to compress in the circumferential direction.Deep drawing. Super-plastic forming Explosive forming Equipments for sheet metal forming. DEFINITION Deep drawing is the manufacturing process of forming sheet metal stock called blanks into geometrical shapes.

This page intentionally left blank. Metal forming third edition. I wish to acknowledge the membership in the North American Deep Drawing Group In analyzing metal forming problems it is important to be able to recognize boundary conditions.Applications Of Deep Drawn Brass. If friction during the process is too great uneven forming or fracturing is likely to occur. The History of Metal Spinning. Become part of North America s largest and most active network of B2B buyers and industrial commercial suppliers.Deep drawing is a sheet metal forming process. Metal sheets are largely used in manufacturing industries due to its easy operation Before discussing its working process first we should learn about main part used in drawing process. These parts are as follow.Deep-drawing. Blank holder helps prevent wrinkling and reduces springback Blank holder not necessary if blank diameter blank thickness is less Closed-loop control of product properties in metal forming A review and prospectus. Journal of Materials ProcessingThis page intentionally left blank. Metal forming fourth edition. 15.1 Cup drawing 15.2 Anisotropy effects in drawing 15.3 Effects of strain hardening in drawing I wish to acknowledge my membership in the North American Deep Drawing Research

Drawing deep drawing -mechanics of drawing analysis others drawing operations defects in drawing 4. Other Sheet Metal Forming Operations -operations performed with metal tooling rubber forming processes.Recent papers in Deep Drawing Cold Forming Metallurgy. A Technological Review of deep drawing process with concentration towards experimental and numerical analysis of sheet metal products of various ferrous and non-ferrous metals using hemisphericalAbstract Deep drawing is a process in which a blank or workpiece usually controlled by a pressure plate is forced into or through a die by means of a punch to form a hollow component in which the thickness is substantially the same as that of the original material.Using sheet metal deep drawing is a process in which a mechanical force radially draws a sheet metal blank into a forming die and transforms its shape. When the depth of the drawn part is more than that of the part s diameter it s then consideremetallurgy - metallurgy - Metalworking Metals are important largely because they can be easily deformed into useful shapes. Literally hundreds of metalworking processes have been developed for specific applications but these can be divided into five broad groups

Forming The sheet metal shaping has been accomplished for thousands of years and The not deep drawing was an evolution notably widespread even if it is possible that Sheet metal is fundamental As you can see the sheet metal history has accompaniedOver the history of metal stamping forging and deep drawing presses of all types are the backbone of metals manufacturing. The processes continue to evolve and improve in moving more metal in one stroke of a metal stamping press. Press and interconnected automation devices increase productionMetal forming and machining are the two prominent methods to convert raw material into a product. Changing the shape of the material by permanent plastic deformation The metal forming machine process is classified into - bulk forming and sheet forming processes.

Deep Drawn Stamping The Crosby Company

Deep Drawing dan Drawing - Renviletieft Blog

Into The Deep Art Print by Kerby Rosanes Art prints

Pin by Nane Babayan on Tattoos in 2021 Deep art Art

Clipart - Diving Helmet

Sea creatures 1 stock vector. Illustration of octopus

When Friends Turn Feral A Review of Fox by Margaret Wild

Imperial Deep Fryer Wiring Diagram